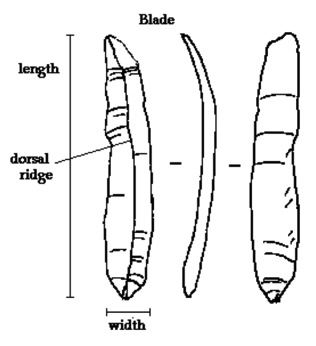

Specialized flake with parallel or sub-parallel lateral edges; the length is equal to, or more than, twice the width. Cross sections are plano convex, triangulate, sub triangulate, rectangular, or trapezoidal. Some have more than two crests or ridges. Associated with prepared cores and blade technique; not a random flake (Crabtree 1982,16).

A blade is technically defined as any flake that is more than twice as long as it is wide, with more or less parallel edges. Whittaker 1994, 33.

Blades may be produced with hard hammer technique, but most often soft hammer and indirect percussion is used. The exact measurable limits for a blade vary widely. These are normally defined by whichever typology is currently in use in the area of investigation. There is general agreement on the length/width ratio of > 2, however, the maximum width can be set anywhere between 8mm (Helskog et al 1976.), 10mm (Hahn 1977, 44 and Hahn 1982, 26-27), 11mm (Taylor 1962, 425-426), and 12mm (Tixier 1974 7). There are normally no maximum length measurements for blades.

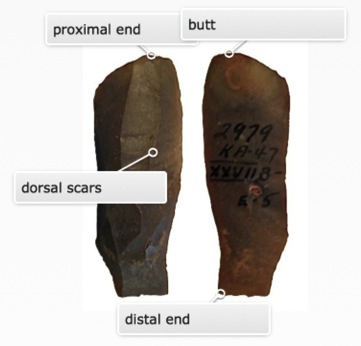

Blades are oriented exactly the same as flakes, with the bulb of percussion down and the dorsal surface up

.